How to setup your Suspension correctly

Author: Jason Date Posted:31 May 2024

A Blog to help you get the most out of your Vehicle and have it set up right for your needs.

Important Notes for setting up your Vehicle Correctly:

We can't Stress this enough....

The biggest mistake we see by far is people ordering Springs Front and Rear to suit "Planned Future Mods" or Loads that are "Occasional" and not "Constant" Loads!!

We have seen many Suspension Manufacturers end up with a "Bad Reputation" through no fault of their own due to people complaining about rough riding suspension or failed components & when you dig a little deeper into the problems they are having, most of the time this just comes down to very poorly setup vehicles.

Front Suspension, all vehicles:

When selecting Front Springs to suit your lift, please only select springs only to suit Current Accessories fitted to the vehicle.

If you order Springs now to suit a Bullbar you are thinking about buying in the future sometime, you are going to hate your car until that Bullbar is fitted & most likely destroy your new Shocks/Struts in the meantime.

Fitting a Front Spring that is designed for a Bullbar, or Bullbar & Winch etc without these fitted will cause big issues.

You also need to take into account the items you take off your vehicle to fit your new accessories.

For Example: To fit a Bullbar on a Ranger, BT-50, D-Max etc you pull about 12kg-16 of Factory Bar, Reinforecement Brackets & Foglights etc off to fit a Bullbar to it

Then you add a Bullbar at approx 70kg, and a winch at approx 30-35kg & most people will go for a 100kg + Front Spring thinking that is how much they are adding, without minusing the weight of what came off.

Total Weight added with 100kg of Accessories may only end up be 84-88kg of additional weight over the nose.

Keep this in mind when ordering your Suspension.

Example:

A 50mm raised Coil Spring to suit no accessories will give 50mm of lift.

A 50mm raised Coil Spring designed for a vehicle with approx 60-80kg of accessories "like a bullbar" will give 50mm of lift with these accessories fitted.

If you do not have these accessories fitted, the vehicle may go up 60-75 or even 80mm in the front end depending on what spring is chosen and it will "Top Out" the Shock or make it hit the upper bumpstop on some IFS vehicles and ride like a brick.

This will also void your warranty on your brand new suspension!

This applies to all vehicles, but for Modern Independent Front Suspension Vehicles, the complexities increase.

IFS Front Suspension:

IFS Vehicles are always going to have a Limited range of up and down travel available.

All you can ever do is move the Control Arms up and down between the Bumpstop on Compression and whatever limits the Downtravel or "Droop" on the front end, which can be Upper Bumpstops on some Vehicles, but on most the Limiting Factor is the range of Articulation in Steering Rack Ends or Tie Rod ends.

Lets say you are able to achieve 10 inches of total Travel in the front of your IFS Vehicle between full Compression and Droop.

In all honesty you are far better off having something around a 2" Lift that offers good suspension travel in both directions, rather than going as high as possible for the mall crawler look and end up with only a with a tiny amount of Droop left and just lift wheels everywhere offroad.

Big Lifts on IFS vehicles are always a comprimised setup unless you want to go to the huge expense of doing a Trophy Truck style of setup.

IFS Geometry:

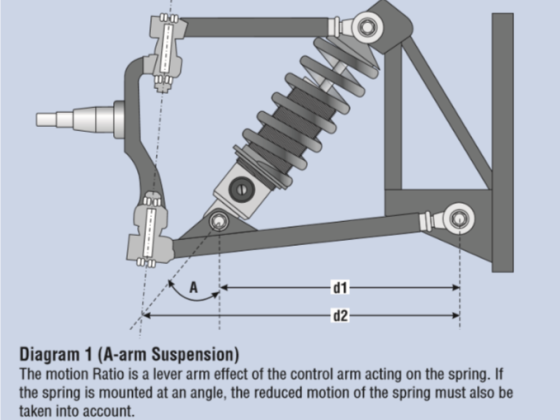

All IFS Vehicles work on a Motion Ratio. This ratio can differ greatly from vehicle to vehicle due to the Strut being mounted at different points along the Lower Control Arm, and mounted at different angles which changes the Motion Ratio.

Example:

So what does this mean?

A vehicle with a 1.7:1 front end ratio will gain 17mm of lift at the wheel with a springs that is 10mm taller than the factory coil.

A vehicle with a 2:1 Ratio will gain 20mm of lift at the wheel with a spring that is 10mm taller than the factory coil.

This means the Spring Length and Rate needed for different loads or heights on a vehicle can vary greatly.

If the Springs aren't properly matched to the weights, even a small change in spring Rate or Length can have big impacts on the ride height at the wheel, let alone the ride quality.

Lets use some all new D-Max or BT-50 Springs for example & I'll try to keep this simple.

The Factory Coil is approx 570lb Rate and the coil is 360mm Free Height.

A Raised No Load Coil to suit an all new D-Max or BT-50 can be a Spring Rate of 660lb with a coil Free Height of 375mm.

This new Coils Installed Height with the vehicle sitting on the ground with 2000lb of load on each coil is approx 298mm with no accessories, and this gives the vehicle approx 50-55mm of lift at the wheel.

Fit a HD coil to that same car with No Accessories on it and things change a lot.

A HD (Bullbar and Winch) Coil for a D-Max or BT-50 depending on what other accessories are fitted is up to a Spring Rate as high as 800lb

The 800lb Coils Free Height is 5mm shorter than the No Load Coil at 370mm, but this does not mean the vehicle will sit lower which is a common misconception people have when they just sit coils side by side.

As the Spring Rate is higher, the HD coil will not compress as easily under load.

Apply the same "No Accessories" load of 2000lb on each HD coil installed in the vehicle and it's installed height is approx 309mm if you don't have any accessories fitted to it.

In a D-Max or BT-50 for instance this equates to approx 20.9mm extra increase in lift at the wheel.

So now, you've ended up with a total lift of approx 75-80mm, but you need to also take into account that this coil will not compress anywhere near as much under load & will also cause the front end to rebound harder over any bump without the weights on the front of the vehicle that the heavier coil is designed for.

This causes the Struts to "Top Out" or essentially try to Stretch itself further than is possible as it runs out of Downtravel or "Droop" and can rapidly lead to leaks or failure.

Sometimes within days!

This will also void your warranty on your brand new suspension.

If you see a Strut that looks like this one below, 9 times out of 10 it has happened due to the vehicle sitting too high and causing the Strut to "Top Out" internally until it pulled itself apart.

You can see on the lower bush that it has been essentially jackhammered right down to the lower edge of the bush eyering from it trying to pull down constantly until it let go.

Strut Top Spacers:

In our opinion, a Strut Top Spacer should Never be used in conjunction with a Raised Spring and Strut setup, and even on a standard Strut setup they are only a stopgap measure & i'll explain why.

Fitting a Strut top spacer, even one as small as 10mm can have big impacts on the vehicle besides the obvious ride height change.

Lets use an IFS vehicle with a 2:1 Ratio for example.

A 35mm Strut Top Spacer will give 70mm of lift to the front end.

The Strut is usually what limits Downtravel or "Droop" on an IFS front end, and its Open Length is set as such to protect components like Ball Joints and Steering parts from being pushed outide of their working range of Articulation.

Depending on the vehicle problems can occur like the Upper Control Arm hitting the Spring on Downtravel or much worse, the Upper or Lower Ball Joint or a Rack End or Tie rod End running out of Travel & failing leading to loss of steering.

If you combine the Strut Top Spacer with an Aftermarket Longer Travel Strut, these issues really begin to compound.

For example, the 70mm of lift given by the Spacer, plus possibly up to 50mm or greater of Extra Downtravel or "Droop" offered by the longer Aftermarket Strut can often lead to rapid failure of a Ball Joint or a Critical Steering Component often with catastrophic results.

This will also void your warranty on your brand new suspension!

Example pics below:

The other downside and Danger of Strut Top Spacers is the increase in Closed or Compressed Length they give the Strut.

This causes catastrophic issues as the Strut is now so long that when you hit a bump, even just everyday speed humps on roads, the Bumpstops on the Lower Control Arms can no longer contact the Chassis effectively to absorb the hit and protect the Strut.

This turns your expensive new Struts into a pair of Bumpstops (which they were never designed for) and Bottoms them out internally until imminent failure occurs.

We often hear people say, Ahh it'll be ok, i dont really go offroad, but failure can easily occur just driving it around on a daily basis on the road.

If you see a strut with a lower leg bent over or crushed like this pic below, you can almost guarantee it was caused by the factors mentioned above.

Classic Example:

Rear Suspension:

When selecting Leaf Springs or Coil springs to suit your lift, please Select Springs only to suit Current "CONSTANT" Loads.

Towing Loads are Not included in your Constant Load Calculations, as they are Not "CONSTANT" Loads.

Please do not put Occasional Loads into your "Constant" Load determinations when setting up your vehicle.

You also need to take into account the items you take off your vehicle to fit your new accessories.

A lot of people remove their Factory Tubs and fit a Tray setup nowadays & nearly every customer we speak to only talks about the weight going on and doesn't take into account what weight came off.

Most Factory Tubs weigh around 125-130kg & this Must be Minused off your Weights of the new Tray you replace it with.

For Instance, if you fit a 250kg Steel Tray, you are really only adding around 125kg on to the vehicle, not 250kg.

If you are only fitting an Alloy Tray, a lot of those come in at 25-30kg, so your Vehicle is actually around 100kg Lighter than it was new, so in this case an alloy Tray and Toolbox setup may be no heavier than the car was new.

Keep this in mind when ordering your Suspension.

Example:

50mm Raised 300kg Constant weight Leaves or Coils are designed to give 50mm of lift with 300kg of CONSTANT weight on them. Put these in with zero load and you could see the rear go up 75-100mm and Leave you with limited droop and it will ride awful empty.

50mm Raised 500kg Constant Leaves or Coils are designed to give 50mm of lift with 500kg of CONSTANT weight on them. This vehicle could potentially sit 100-125mm+ up with no load & will destroy components in no time and ride extremely rough.

Selecting a load rating that is too heavy for your setup will result in Poor Flex Off-Road, Compromised Suspension Travel & Rough Ride.

It will cause damage to your new shock absorbers and other components by pushing them outside of their intended working range

This will also void your warranty on your brand new suspension!

If you have Heavy Occasional Loads, Airbags are the only option that will properly work for your Vehicle.

Airbags:

Note: Airbags do NOT break Chassis, People break Chassis.

This usually happens by far overloading vehicles, often with Aftermarket Trays or Canopy Setups that are far longer than recommended for the vehicle, and then trying to pump the airbags back up to get it level again.

An all too common example of how chassis breakages occur:

Vehicles that the owners have already loaded up & running at full GVM, then you hook a Trailer which adds more weight over the rearmost point of the chassis, puts the vehicle way over GVM and they just pump the bags up and kill the poor thing......... Then blame the Airbags for snapping the grossly overstressed chassis.

Like anything.... Use them properly within the load limitations of the vehicle and they are perfect for what they are designed for.

A Classic Example of what we have mentioned above. Airbags did NOT break this vehicle, poor setup and overloading broke it.

.jpg)

What are we trying to say in all of this?

Do it once, and do it right.

We always try to tell people to set the car up first with all of your accessories, and then do the Suspension Kit to suit it last.

This is the Only way to set it up correctly to ensure proper load carrying ability, ride quality and optimised suspension travel.

This will always give the best results, as no matter how many times we try, people will order heavy springs for something they plan on doing weeks, months or years down the track...... Then they spray the Supplier or the Suspension company online saying how s**t the Suspension is & how terrible it rides, when in all reality the vehicle has just been set up poorly through bad choices.